Manufacturing technologies for commutators

Glassband technology

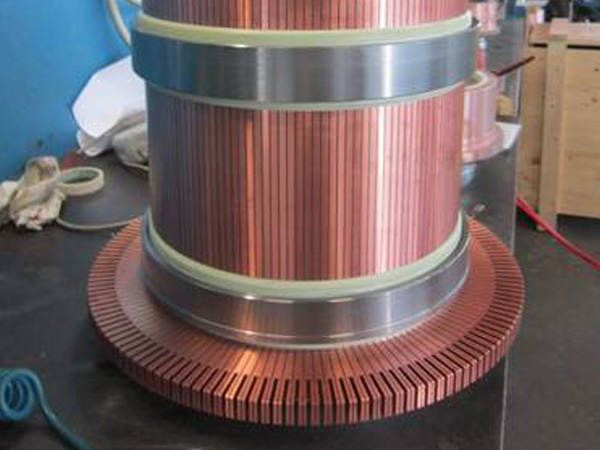

The glassband technology is much more modern than the one used in the V-Ring version, and consists of fibre glass band mixed with resins that polymerize over certain temperatures to give resistances which can be compared to the one of steel. This technique is used for special series of industrial commutators or on request. The copper body held together by the banding is normally shrunk onto an insulated steel body to give a single compact piece which can reach high rotation speeds even for very long commutators.

1. STANDARD

2. WITH FLAG RISERS

3. JOINED COPPER SEGMENTS

Manufacturing technologies for commutators

Glassband technology

The glassband technology is much more modern than the one used in the V-Ring version, and consists of fibre glass band mixed with resins that polymerize over certain temperatures to give resistances which can be compared to the one of steel. This technique is used for special series of industrial commutators or on request. The copper body held together by the banding is normally shrunk onto an insulated steel body to give a single compact piece which can reach high rotation speeds even for very long commutators.

1. STANDARD

2. WITH FLAGS RISERS

3. JOINED COPPER SEGMENTS

Glassband commutators

1. Standard

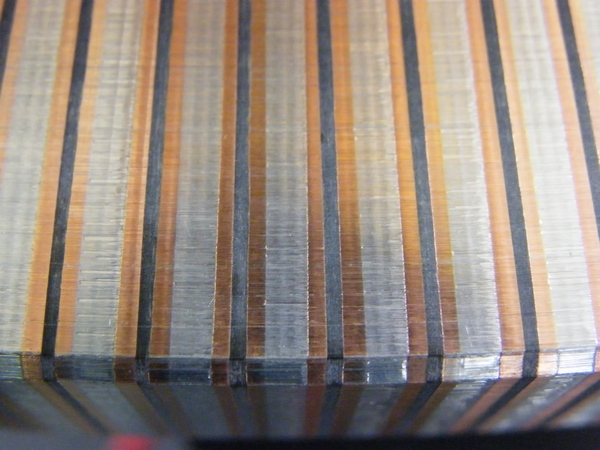

This construction is the most common type. The trapezoidal section segments are procured on the market, or drawn directly in the company starting from raw copper, to get the desired section and hardness.

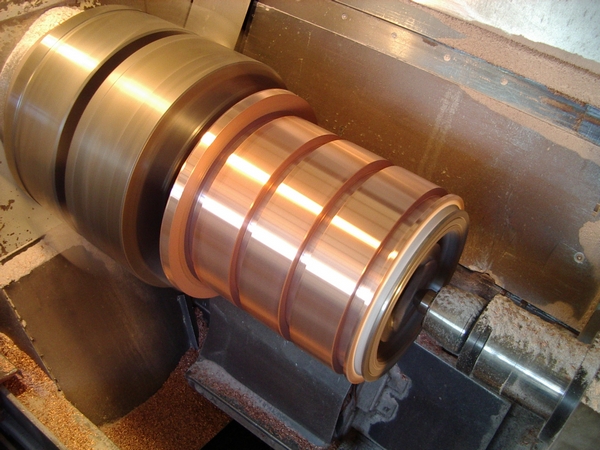

The commutator copper segments are monolithic and the riser is obtained by CNC machining, or turning, to achieve the requested dimensions.

The commutator copper segments are monolithic and the riser is obtained by CNC machining, or turning, to achieve the requested dimensions.

Glassband commutators

1. Standard

This construction is the most common type. The trapezoidal section segments are procured on the market, or drawn directly in the company starting from raw copper, to get the desired section and hardness.

The commutator copper segments are monolithic and the riser is obtained by CNC machining, or turning, to achieve the requested dimensions.

The commutator copper segments are monolithic and the riser is obtained by CNC machining, or turning, to achieve the requested dimensions.

Glassband Commutators

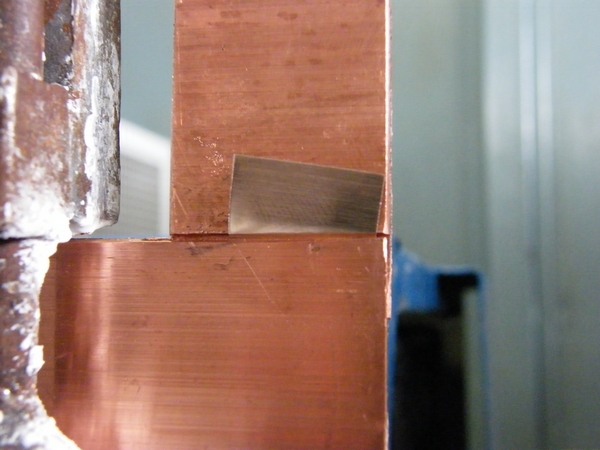

2. With flags risers

This version is obtained thanks to the process of silver brazing of copper flags of various types and geometries, depending on the customer's request, with the original monolithic copper segments, in order to achieve the required crown diameter.

This technology is usually helpful when the gap between brush track and riser diameters is significant, which would result to the impossibility of a full segment realization or to expensive production costs.

This technology is usually helpful when the gap between brush track and riser diameters is significant, which would result to the impossibility of a full segment realization or to expensive production costs.

Glassband Commutators

2. With flags risers

This version is obtained thanks to the process of silver brazing of copper flags of various types and geometries, depending on the customer's request, with the original monolithic copper segments, in order to achieve the required crown diameter.

This technology is usually helpful when the gap between brush track and riser diameters is significant, which would result to the impossibility of a full segment realization or to expensive production costs.

This technology is usually helpful when the gap between brush track and riser diameters is significant, which would result to the impossibility of a full segment realization or to expensive production costs.

Glassband Commutators

3. Joined copper segments

The manufacturing with joined copper segments is a hybrid that has the advantages of the flag risers version, when the gap between the brush track and riser diameters is significant, but it does not have flexible flags, as full copper extension segments are used, joined to the original copper segments by means of silver brazing.

This solution helps when the requested geometry is not reachable with the standard full copper segment version, because of manufacturing issues, or to contain the costs. The commutator copper body is then turned and manufactured a standard version one.

This solution helps when the requested geometry is not reachable with the standard full copper segment version, because of manufacturing issues, or to contain the costs. The commutator copper body is then turned and manufactured a standard version one.

Glassband Commutators

3. Joined copper segments

The manufacturing with joined copper segments is a hybrid that has the advantages of the flag risers version, when the gap between the brush track and riser diameters is significant, but it does not have flexible flags, as full copper extension segments are used, joined to the original copper segments by means of silver brazing.

This solution helps when the requested geometry is not reachable with the standard full copper segment version, because of manufacturing issues, or to contain the costs. The commutator copper body is then turned and manufactured a standard version one.

This solution helps when the requested geometry is not reachable with the standard full copper segment version, because of manufacturing issues, or to contain the costs. The commutator copper body is then turned and manufactured a standard version one.

3.Collettori a LPR

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore te feugait nulla facilisi.

Let’s get in touch

What can

we do for you?Contacts

Call us